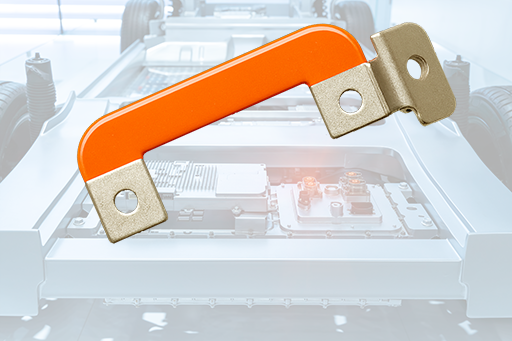

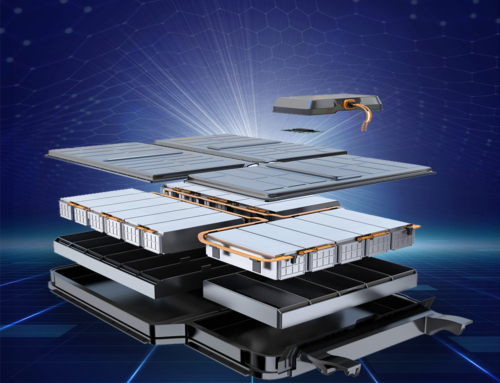

Busbars play a central role in modern energy and drive technology: they are used for reliable, low-loss power distribution in electrical systems and battery storage systems, both for large battery systems and for high-voltage batteries and electric vehicles (EVs). The choice of insulation and protective coating is crucial to the longevity, safety and efficiency of the system.

Particularly in stationary energy systems (e.g. medium-voltage distribution systems, DC power supply systems) and large battery systems (e.g. storage farms, container solutions, industrial UPSs), the appropriate coating technology for copper or aluminum busbars is a safety-relevant aspect. The same applies to the high-voltage range of EV batteries, but a different high-voltage training is required here.

Two of the most common methods for busbar coating are:

- PVC dip coating (dip coating)

- Epoxy resin powder coating (Epoxy Powder Coating)

This article provides a well-founded comparison of both methods based on their technical properties, typical areas of application and relevant standards.

1. PVC dip coating

PVC dip coating is a tried-and-tested process in which the conductor rail is dipped into a liquid plastic bath and then dried. The resulting layer is elastic, adhesive and electrically insulating.

Properties:

- Insulation voltage: approx. 3,500 V AC

- Temperature range: -40 °C to +125 °C

- Flame protection: UL94V-0

- Chemical & UV resistance: good

- Flexibility: very high

Advantages:

- Ideal for complex geometries and vibration influences

- Low costs in series production

- Good repair options in the event of damage

Application examples:

- DC power distributors in building technology

- Low-voltage systems in switch cabinets

- Intermediate wiring in battery storage systems

2. epoxy resin powder coating

In epoxy powder coating, a thermally curing epoxy powder is applied electrostatically and baked in an oven. The resulting coating is hard, resistant and permanently protective.

Properties:

- Insulation voltage: up to 5,000 V AC

- Temperature range: -40 °C to +150 °C

- Flame protection: UL94V-0

- Chemical & UV resistance: very high

- Mechanical load capacity: excellent

Advantages:

- Particularly suitable for high voltages and harsh environments

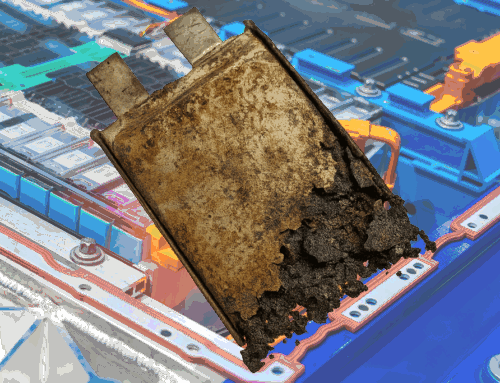

- Long-term stability, corrosion-resistant

- Good adhesion even under high thermal loads

Application examples:

- Busbars in high-voltage storage systems (EV battery, BESS)

- Traction applications in vehicle construction

- Offshore and chemical plants

3. systemic comparison

| Criterion | PVC dip coating | Epoxy resin powder coating |

|---|---|---|

| Insulation voltage | ~3.500 V | ~5.000 V |

| Temperature resistance | up to +125 °C | up to +150 °C |

| Mechanical strength | medium (elastic) | high (hard, resistant) |

| Repairability | good | limited |

| Vibration resistance | very good | good |

| Chemical resistance | good | very good |

| Production costs | low | medium to high |

| Typical applications | Low voltage, flexible systems | High voltage, industry, EV |

4 Conclusion for practice

The following applies to training and planning contexts in electrical engineering:

- PVC dip coating is ideal when cost efficiency, vibration resistance and subsequent machinability are paramount. Ideal for installations in building and distribution technology, even for medium-voltage applications.

- Epoxy powder coating is the first choice for fatigue strength, high voltage and environmental impact – especially for EV battery components, industrial busbars or critical storage systems.

Anyone who is familiar with these differences in training practice can prepare targeted content for safety officers, planners or maintenance staff that reflects the state of the art.

Leave A Comment