From energy density to propagation protection – technical keys for long-lasting lithium-ion systems in vehicles; why the application dictates the design

Whether BEV or HEV – the battery only delivers when cell chemistry, cell design, pack architecture, BMS and thermal management are coupled to the real application. Range demands energy density (BEV), recuperation and peak power force power density (HEV/PHEV). In between, the

Electromobility: range, energy density and the thermal window

Energy density as the primary goal

For BEVs, the specific energy/energy density sets the pace. The leap in scale mentioned in the literature today: from over 200 Wh/kg at battery level in the direction of doubling – whereby the major leverage lies in material and cell design (e.g. Si/Si-C anodes; cathodes with higher open-circuit voltage). This is the only way to achieve the required range in the long term. Pack lightweight construction and module design help, but are secondary to cell advances.

System sizes and mileage targets

In passenger cars, BEV batteries are typically in the 50-100 kWh range; in the commercial vehicle sector, the pack size is significantly higher – 350 – 650 kWh for buses. The fixed routing (scheduled services) facilitates charging management – in technical terms, the control of large heat flows and propagation remains central.

Fast charging is thermal management

Charging power that exceeds the classic Mode 3 AC chargers of 11kW or 22 kW is challenging in terms of infrastructure and thermal requirements: internal resistance and temperature level determine the power to be released. As the SoC and temperature drop, the DCIR increases, charging and driving performance collapse – the operating strategy and preconditioning must take this into account.

Hybrid vehicles: power density, microcycles, robustness

P/E ratio makes the difference

Hybrids operate in narrow SoC windows with many microcycles and high pulse currents. In current xEV systems, the average

Cell and material decisions

High-power cells require low internal resistance, robust contacting and very homogeneous cooling. In niches with extreme C rates, anode variants such as LTO score points: exceptionally cycle-resistant and safe, but suitable for low energy density where power robustness takes precedence over capacity.

Thermals as a life cycle driver

Short, high pulse currents create hot spots. Keeping ΔT low reduces drift, balancing effort and impedance rise. Hybrids in particular benefit disproportionately from clean

BMS, operating strategy and real performance limits

Sensors, models, release

An effective BMS measures cell voltages, currents and temperatures, balances SoC/SoH and releases the permissible (de)power via SoF (State of Fitness). Without

Infrastructure influences suitability for everyday use

From 3 kW home charging points to fast-charging scenarios: The charging concept shapes usage. Fast charging requires adequate infrastructure and thermal design; range extender concepts are repeatedly discussed, but remain application specialties.

Safety: Prevent – Detect – Limit (layer principle)

Multi-level protection across all integration levels

Experts emphasize the safety assurance of the cell, module, battery and vehicle – fromthe Abuse test to the crash test, in accordance with common norms/standards (IEC/ISO/DIN/SAE, UN transport, OEM specifications). The aim is to optimize functionality and costs while maintaining a constant level of safety – with the highest possible intrinsic cell safety, so that the validation effort at higher levels remains manageable.

Functional safety and requirements management

Safety work is not just a test, but a process: hazard analysis, risk assessment and normative requirements management ensure that the right verifications/validations are carried out – more important than ever in the changing conditions of electromobility, for which specialist high voltage (ev) personnel in development and production are absolutely essential.

Standards and electrical safety

For electrically powered road vehicles, ISO 6469-3, among others, sets standards for protection against electric shock; at cell level, EN 62660-1/-2 addresses performance and Abuse tests. Charging and plug-in systems are regulated by IEC series. All in all, these standards define the safety “guardrails” from insulation coordination to charging compatibility.

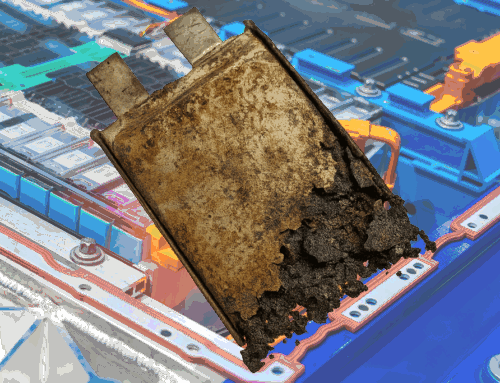

Operational levers for service life and performance

- SoC window & temperature control

Aggressive margins (near 0%/100% SoC, low temperatures) increase DCIR, plating risk and fade. Operating strategies therefore limit power depending on temperature and SoC and condition before fast charging. - Thermal homogeneity (ΔT)

Small ΔT across module/pack = even ageing, less drift, less balancing losses-essential for HEV continuous power and BEV fast charging. - P/E-compatible component selection

Current paths, contactors, fuses, cooling channels and BMS algorithms are dimensioned to P/E target and load spectrum – one scheme does not fit for HEV and BEV. - Commercial vehicles & fleets

Larger packs (bus) benefit from a defined route; this simplifies loading windows, but increases the requirements for heat dissipation and propagation control.

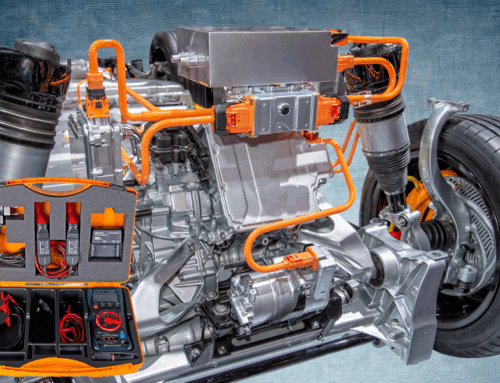

A sentence on the low voltage situation: < 60 V vs. (ev) high voltage (≥ 60 V)

Low voltage (< 60 V DC) and high voltage (≥ 60 V DC) differ not only technically (insulation coordination, HVIL, shutdown paths), but also in terms of capability and responsibility. This is important in day-to-day business – details belong elsewhere in the qualification line; here it is sufficient to remember that different work must be released differently. (Specific standard points on HV (ev) protection and charging interfaces underline this separation).

Practical conclusion

- BEVs need maximum energy density without breaking the thermal window. Material advances (anode/cathode) remain the main lever, lightweight system design the second. Fast charging is a question of DCIR, temperature and operating strategy – not just the connector.

- HEV/PHEV are power projects: low internal resistance, powerful cooling, high cycle stability and narrow SoC windows; niche chemistries like LTO can be the more robust choice here.

- Safety is created in layers: intrinsically safe cell, valid module/pack architecture, BMS with real diagnostics and a test/standards set that covers everything from abuse to crash – including process-related safeguarding through requirements/safety management.

Those who design in this way cover range, performance, service life and safety with real data and deliver systems that stand up in the field: from compact PHEV packs to large BEV drives. For electrical engineers and those responsible for battery production, this means that those who understand battery requirements at this level can build systems that are efficient, safe and economical – in the laboratory, on the line and in the field.

PS: Our recommendation: Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 things you need to know in advance about the high-voltage qualification of your employees” is available here (click).

Leave A Comment