How traction batteries convince after the car in stationary and mobile applications – and what engineers and decision-makers need to pay attention to.

Why Second Life makes technical sense

Traction batteries are the most valuable and complex part of electric drives – and they age. At the end of automotive use, their condition determines the next step: reuse in the vehicle, reassignment to less demanding applications (“second life”) or dismantling/recycling. This path decision is not a gut feeling, but follows measurable parameters such as capacity, internal resistance and freedom from defects.

The rededication to stationary or semi-stationary storage (e.g. PV intermediate storage, construction site or emergency lighting supply) as well as mobile uses with moderate dynamics (e.g. industrial trucks) is particularly attractive. These categories – stationary, semi-stationary, mobile – structure the requirements and help with the selection of suitable batteries.

From the cell to the system: what really counts

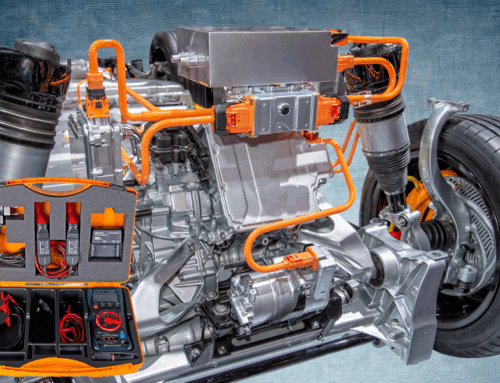

Technically speaking, a battery is more than the sum of its cells. For safe operation, cell voltage, temperature and battery current must be continuously monitored; typical Li-ion cells operate around 3.6 V nominal voltage, with limit values that can lead to degradation and even safety risks if exceeded or undercut. A modern system includes modules with cell monitoring and balancing (CSC/ASIC), a control unit for SOC/SOH calculation and power management, (ev) high voltage contactors and current measurement – often redundant.

Why is this so important? Because the subsequent second-life load profiles (e.g. many flat cycles in grid operation vs. several hours of cycling in home storage) directly determine life expectancy, efficiency and safety – and therefore whether a used traction battery is suitable for the target profile at all.

Measuring instead of guessing: Determine SOC, DOD, SOH accurately

Solid condition diagnostics are the ticket to any reuse project. The state of charge SOC is the ratio of the currently charged Ah to the available capacity; the depth of discharge DOD is calculated as 100 % SOC. The state of health SOH is defined as the ratio of the current full capacity to the nominal capacity; below a typical threshold value of around 80 %, this is referred to as the end of the original service life (depending on the application).

From an engineering perspective, this means that no second-life release is possible without reliable SOH, SOC and internal resistance diagnostics – ideally with reproducible test procedures that map the target profile (currents, temperatures, cycle windows).

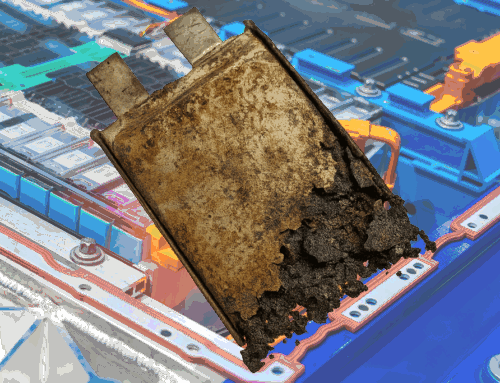

Understanding ageing – planning second life realistically

Ageing is not linear. It is influenced by temperature, current rates and cycle windows; the capacity curve typically flattens out slightly at first before falling more sharply. In second-life scenarios, application ranges above ~50-80 % residual capacity are often used (depending on the specific application) in order to have sufficient reserve for degradation in second use.

Pragmatic examples show that this works: From PV home storage systems to grid-supporting large-scale storage systems and semi-stationary solutions, there are real pilot and practical projects that successfully operate second-life batteries.

EOL-IS as a process concept: from expansion to commissioning

Reuse is a process, not a single step. An end-to-end process – from removal, diagnostics, disassembly/reassembly to integration, testing and commissioning – minimizes risks and costs. The systematic approach behind this: orderly evaluation, data-based assignment to the appropriate application and documented commissioning in the target system.

Engineer takeaway: Define the target use case first (e.g. PV shift vs. grid support). Then set limits for SOH, internal resistance, temperature window, C-rate and approved DOD. Only when the battery has passed these criteria will the conversion be economically viable – and remain safe.

Requirement profiles: stationary, semi-stationary, mobile – short & crisp

- Stationary (e.g. home storage, grid support): more even loads, focus on cycle stability, efficiency and calendar stability.

- Semi-stationary (e.g. construction site lighting): as stationary, but with relocation/transport capability – mechanical robustness and fast recommissioning are important.

- Mobile (e.g. industrial trucks/e-scooters): more dynamic power requirements, significantly higher peak currents – check internal resistance and thermal management particularly strictly.

Suitable batteries are selected on the basis of clear sets of parameters (including capacity, internal resistance, temperature and current range, permissible cycle depth, self-discharge).

Safety first: standards, architecture, operation

Safety comes from chemistry, architecture and operation: robust cell chemistry and system packaging, reliable BMS functions (monitoring, balancing, limit value/fault handling), defined shutdown paths (contactor/fuse), convincing thermal management – and operation that avoids temperature stratification, excessive C rates or unfavorable SoC media.

For stationary/industrial applications, IEC 62619 is the central safety standard at cell/battery level; it defines requirements and tests for the safe operation of secondary Li-cells in industrial and stationary applications. In Germany,

Note on qualification & voltages: Handling systems below 60 V (low/low volt) differs significantly in terms of obligations and hazards from low voltage/high voltage (typically ≥ 60 V DC). Qualification requirements differ accordingly according to German regulations; in the automotive environment, for example,

Data & transparency: where the journey is heading

The EU Battery Regulation (EU) 2023/1542 enshrines sustainability and transparency obligations over the entire life cycle. The battery passport – mandatory from

Engineering consequence: Anyone planning second life today should design data models and interfaces in such a way that future battery fit information (cycles, temperature history, repairs, measurement data) can flow seamlessly into the suitability test and the BMS of the target system.

Mini guide for the technical suitability test

- Define use case: Stationary (PV shift/control power), semi-stationary (temporary supply), mobile (drive/forklift truck). Document load profile.

- Record status: SOH (≥ threshold), SOC window, internal resistance, temperature behavior, fault memory.

- Define system limits: DOD, C-rates, temperature window, permissible imbalance, contactor/fuse design.

- Check safety concept: Conformity with standards (IEC 62619 at battery level; VDE-AR-E 2510-50 at system level if applicable), protection paths, fault reactions.

- Integration & test: BMS connection (SOC/SOH models), balancing strategy, thermal verification in the target profile, acceptance test incl. documentation (also with regard to UN 38.3 transport).

Practical examples – what is important in each case

- PV home storage (stationary): relatively uniform energy consumption with weather-related variations → cycle stability, high round-trip efficiency, robust thermal performance.

- Grid support/peak shaving (stationary): many short load peaks, high demand for low-loss energy transmission and fast controllability.

- Construction site lighting (semi-stationary): repeated assembly/dismantling, changing environment → mechanical robustness, simple commissioning, tolerant thermal conditions.

Conclusion: Second Life can bring a lot, but should be run carefully and purposefully

Second life is technically worthwhile if the data, design and discipline are right. Those who accurately determine the state variables (SOC/DOD/SOH), honestly simulate the target profile and consistently implement standards and safety concepts will obtain economical storage systems with calculable risk – whether in home storage, grid support or semi-stationary applications. The good news is that practical experience and pilot projects are demonstrating feasibility; the next evolutionary stage – battery passport – will further accelerate second life because it will bring transparency and suitability tests that can be automated.

Briefly summarized for electrical engineers and foremen:

- Technology: BMS monitoring, clear limit values, application-oriented system design.

- Safety: Keep an eye on IEC 62619/UN 38.3/VDE-AR-E 2510-50; plan protective paths.

- Qualification: Below 60 V ≠ (ev) high voltage – different hazards, procedures and qualification requirements (e.g. in accordance with DGUV-I 209-093, VDE/IEC).

- Future: Digital data depth (battery pass) makes second life more predictable – use it!

Anyone who works with (ev) high voltage systems bears responsibility for the safety of people, the environment and operations. Solid training – such as battery diagnostics and the specialist high voltage ( ev ) at TCS – is the first step.

PS: Our recommendation: Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 things you need to know in advance about the high-voltage qualification of your employees” is available here (click).

Leave A Comment