Law, technology and safety combined – what the Seveso and accident regulations mean for modern battery technology.

Seveso (EU) and the Hazardous Incident Ordinance (DE) are not “chemistry-only” issues. They apply wherever hazardous substances are present in relevant quantities – i.e. also in battery production (electrolyte, solvents), in test laboratories, in stationary BESS and in recycling. For electrical engineers, the clever dovetailing of system design, electrical protection concept, substance management and safety organization is decisive for approvability, availability and fire protection – and thus for economic efficiency.

1) What it’s all about – and why it directly affects electrical engineering

The European Seveso Directives regulate the prevention of major accidents involving hazardous substances and the limitation of their effects. In Germany, they are implemented via the

Electrotechnical reference: In battery production, large quantities of flammable solvents (e.g. NMP substitutes in cathode/anode coating, washing/cleaning media) and electrolytic liquids are produced; in stationary storage systems (BESS), energy-rich modules are concentrated in housings/rooms; in recycling, hazardous reaction gases can be produced during thermal/chemical decomposition. Whether your site falls within the Seveso scope is determined by the accumulation of hazardous substances in the operating area – regardless of whether the focus is mechanical, electrical or chemical.

2) Duties translated for battery projects

Corporate policy & safety management

Seveso requires an integrated safety concept and a “state of the art” safety organization – with clear responsibilities, maintenance processes, change management (MOC), training and consistent accident/near-accident evaluation. For electrical engineering managers, this means that safety functions (BMS limit values, insulation monitoring, shutdowns, ATEX protective measures, fire protection) must be anchored in the organization and effectively demonstrated.

Safety reports & distances

If the thresholds are exceeded, safety reports, alarm/hazard prevention plans and, if necessary, spatial distances to areas worthy of protection must be submitted. For BESS, for example, this means Fire scenarios, thermal runaway events (propagation), smoke/HF release as well as extinguishing and smoke extraction concepts must be plausibly calculated and interlinked with the electrical design (zoning, current limitation, shutdown logic).

Role of the incident officer

The incident officer advises the operator, monitors compliance with the specifications, reports defects immediately and reports annually – expertise and reliability are regulated. In electrical engineering companies, his active interface with electrical planning, maintenance and operation is crucial.

3) Battery production: from “chemical” risk to electrotechnical implementation

Coating & drying: Solvent-based slurries and electrolyte handling require explosion protection and fire protection concepts. For electrical engineering, this means ATEX-compliant equipment in relevant zones, safe shutdowns, functional safety (SIL/PL) for ventilation, extraction, oven/dryer and interlocked energy supplies. Seveso obligations require proof that technical and organizational measures are suitable for preventing or limiting incidents.

Forming & testing: Exothermic risks arise during initial charging; electrical systems must provide robust current/voltage limits, monitor cells and disconnect them safely in the event of a deviation. The

Power supply & earthing: High short-circuit power in test benches/strings requires selectivity, arc-proof switchgear, equipotential bonding and insulation monitoring. Seveso also requires quality-assured maintenance – inspection plans, test levels, approvals – and the documentation of changes.

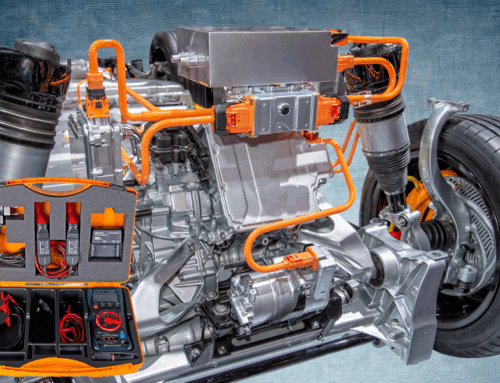

4) Stationary BESS: Seveso meets system and electrical safety standards

There are special safety standards for grid-integrated storage systems that combine with Seveso obligations to form a consistent overall concept:

- IEC 62933-5-2 (Safety for grid-integrated electrochemical ESS): System approach for personal and environmental protection – including electrical, mechanical and fire protection design.

- VDE-AR-E 2510-50: German application rule for stationary Li-BESS – Requirements for installation, operation and testing (widely referenced in projects).

- NFPA 855: Installation standard for ESS (USA), increasingly cited as best practice – chapters on Li-Ion, clearances, room layout, detection, fire compartments.

Classification: Seveso evaluates hazardous substance quantities and requires the management of major accidents. The standards mentioned define

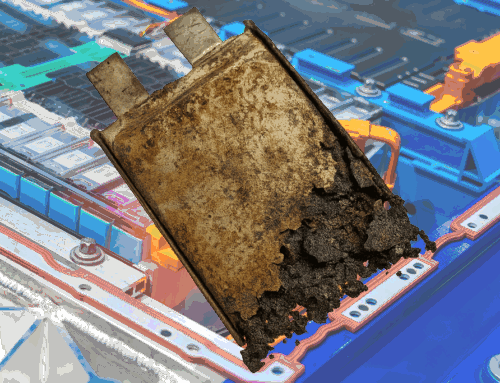

5) Battery recycling: different process routes, same principle

Flammable/reactive gases, acids/alkalis and fine dusts are produced during mechanical, thermal or hydrometallurgical digestion. This increases explosion and fire hazards as well as toxic risks. Seveso requires the same logic for this: check quantity thresholds, define the operating area, draw up alarm/hazard prevention plans, schedule safety reports and on-site inspections. Important in terms of electrical engineering: Dust EX protection, ignition source-free drives, electrical infrastructure with safe disconnection and earthing.

6) Qualification & voltage levels – when it’s more than just cell production

In practice, there are different protection and qualification requirements depending on the voltage level: different rules apply below 60 V DC (extra-low voltage/low-voltage) than in high-voltage systems. For vehicles and related HV (ev) environments, DGUV Information 209-093 describes the qualification and minimum content – from safe operating modes to working in a de-energized state. This logic is applied analogously in many companies for stationary systems and test stations (legally, the specific application is always decisive). So when it comes to entire HV (ev) battery systems instead of just low-voltage modules or individual cells, this also becomes relevant.

7) What authorities expect today – “integrated security” in concrete terms

State-of-the-art safety technology means: continuous adaptation to regulations, approval requirements, official monitoring, open flow of information, training and organization in the event of changes. This is precisely where electrical engineering has many levers: from release logic (hot work, switching measures) to functional safety (SIL/PL) and e-maintenance & test cycles. Near misses are systematically evaluated; safety management assigns clear responsibilities – the incident officer provides technical support and reports.

8) Difference to the automotive world – same cells, different boundary conditions

Even if cell chemistries (LFP, NMC etc.) are similar, the

9) Looking ahead – secure systems through technology and management

Trend 1: Standardization fine-tuning. International/European standards (IEC 62933-5-2, EN IEC 62619, VDE-AR-E 2510-50) are being updated and sharpen requirements for safety functions, tests, clearances and fire management. NFPA 855 acts as an international reference for layout/fire protection.

Trend 2: Chemistry & architecture. Higher proportion of LFP in stationary applications reduces thermal escalation risks; segmentation, rack fire load limitation and propagation tests (e.g. 9540A-based methods in the US environment) improve structural and electrical protection.

Trend 3: Systemic resilience. Authorities are placing greater emphasis on on-site inspections and publicly accessible information on risks/emergency planning; operators are professionalizing incident/alarm drills and dovetailing BMS telemetry with building and hazard management.

Conclusion: Thinking Seveso means thinking “electrical safety system”

The following applies to battery production, stationary ESS and recycling: Seveso/incident law addresses the major risks – and electrical engineering provides central protective functions. Those who check early on in the project

- Material balance & scenarios (electrolyte, solvents, reaction gases) → Clarify operating range and obligations.

- Technology & organization as a unit: BMS limits, shutdown, ATEX protection, fire protection, MOC, exercises.

- Use standards: IEC 62933-5-2, VDE-AR-E 2510-50, (where appropriate) NFPA 855 for system/layout safety.

- Note qualification: Distinguish between below/above 60 HV (ev) DC; for vehicle HV, DGUV 209-093 is the standard – the logic is transferable to related environments.

This turns a “chemical regulation” into an electrotechnical management tool: for safe, permit-proof and economical battery locations – from the cell to the megawatt storage system. Anyone who works in the field of (ev) high voltage systems bears responsibility for the safety of people, the environment and operations. Solid training – for example on

PS: Our recommendation: Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 things you need to know in advance about the high-voltage qualification of your employees” is available here (click).

Leave A Comment