From OCV, DCIR & EIS to round/prismatic/pouch and thermal runaway – the practical guide for battery production and development

Why cell knowledge is the basis of every battery production

Those who understand cells make the right system decisions: Characterization shows what a cell can do; construction & design determine integration, thermal and service; mechanics influence performance and service life; aging explains capacity and performance degradation; service life prediction makes projects calculable; safety decides on release – and ultimately on reputation. This technical article bundles the core topics at cell level – compact, resilient and with clear action points for electrical engineers and those responsible for battery production.

1) Cell characterization: metrics, methods, pitfalls

The key parameters

- Capacity / energy / energy density (gravimetric & volumetric): Only valid with defined C-rate protocol and temperature window.

- DCIR (direct internal resistance): Short-term load step measures voltage drop – central to performance, thermal management and charging capacity.

- EIS (Electrochemical Impedance Spectroscopy): Breaks down resistance components (ohmic, charge transfer, diffusion). Ideal for fault diagnosis and ageing tracking.

- Coulombic efficiency (η): Early indicator for side reactions (lithium loss); small deviations add up over cycles.

- OCV-SoC characteristic curve: foundation for BMS calibration, SoC estimation and pack balancing.

Test protocols that provide comparable data

- CC-CV under close temperature control, defined relaxation times before measuring points.

- HPPC profiles (Hybrid Pulse Power Characterization) across the SoC range for charging/discharging power.

- Temperature tests (low/high) – Ageing mechanisms are temperature-dependent.

- Ensure reproducibility: same preconditioning cycles, same fixture/lines, same measuring device class.

Remember: Figures are only as good as the protocol. If you do not supply the C-rate, temperature, pauses and device calibration, you will not provide comparable figures.

2) Shapes & designs: round, prismatic, pouch – consequences in practice

Round cells (e.g. 18650, 21700)

- Pros: robust housing mechanics, mature mass production, good surface/volume ratio for small diameters.

- Cons: many individual cells in the pack; complex connection and monitoring topology.

- Consequence: modular, easy to automate; propagation (thermal runaway propagation) can be controlled via spacers/brackets.

Prismatic cells

- Pro: very good volumetric packing density, stable housing, established automotive integration.

- Contra: longer heat paths to the center of the cell; tab design and contacting become more critical.

- Consequence: early coupling of installation space and cooling design (bottom/side/intermediate layer cooling).

Pouch cells

- Pro: best volumetric utilization, flexible formats, low housing weight.

- Contra: low inherent rigidity, sensitive to swelling and mechanical stress; tightness (sealing) highly critical.

- Consequence: stack pressure management (defined compression), degassing steps in production, robust packing mechanism to prevent pillow-ing.

Practice: There is no such thing as the “best” design. The decisive factor is the system compromise between installation space, thermal, performance, crash/propagation strategy and service.

3) Mechanical aspects: Stack pressure, swelling, contacting

Understanding swelling – and countering it correctly

Swelling is caused by lithiation (especially on the anode) and by gases from side reactions. Without controlled compression, contact resistance increases, tabs fatigue and local hot spots occur.

- Too little pressure: contact losses, increasing DCIR, uneven current distribution.

- Too much pressure: mechanical damage (binder breakage, particle cracks), increased calendar ageing.

Contacting & current paths

- Welding processes (ultrasonic/laser) must ensure reproducible low contact resistances.

- Keep current paths symmetrical and short – reduces ohmic/inductive losses and temperature gradients.

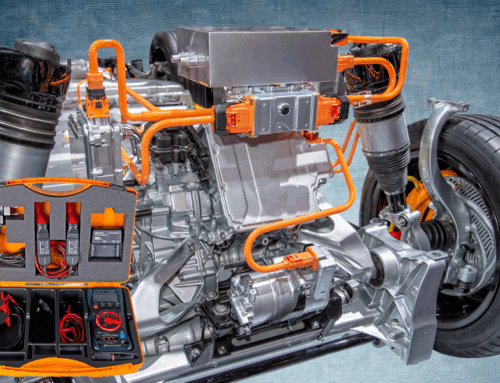

Cell in a pack: mechanical integration

- Vibration/crash: decouple bearings, defined load paths, support concepts for each design (pouch needs more structure, prismatic uses housing, round cell uses holder + winding direction).

- Thermal expansion: Dimension compression frames and elastomers so that the compression windows are maintained over the life cycle.

Remember: mechanics is electrical performance. Stack pressure and contacting are levers for range and charging performance.

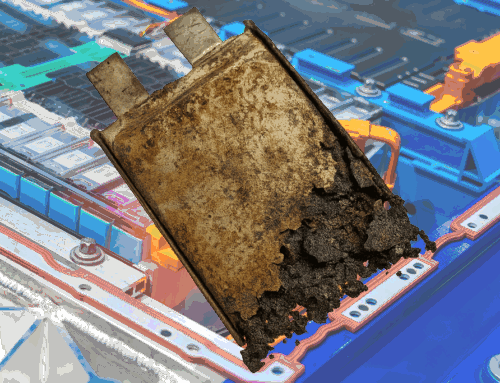

4) Ageing: chemical, mechanical and electrical causes – and their signatures

Overview of the main mechanisms

- Loss of Lithium Inventory (LLI): SEI growth actively binds lithium → capacity fade, η < 100 %.

- Loss of Active Material (LAM): particle cracks, delamination; at the cathode additional phase changes and transition metal dissolution (e.g. Mn) → impedance increase.

- Electrolyte/additive degradation: increased at high voltages/temperatures → gassing, CEI changes.

- Mechanical mismatch: incorrect compression, cyclical stretching (pouch), tab fatigue → IR rise, hot spots.

Stressors with great leverage

- Temperature: increases reaction kinetics (Arrhenius) → faster fade.

- SoC window: Operation close to 0 % or 100 % SoC promotes side reactions; moderate range (e.g. 10-90 %) contributes to service life.

- C-rate & fast charging: high charging rates increase the risk of Li-plating – especially when cold. Preheating beats “cold fast charging”.

- Deep cycles vs. micro-cycling: both can be critical – the decisive factor is the real load spectrum.

Diagnostic signatures

- DCIR increase and EIS shift (charge transfer, Warburg) show increasing impedance.

- dQ/dV analysis (or dV/dQ) shifts peak structures – an indication of phase changes and LAM.

- η-decline (Coulombic Efficiency) indicates growing side reactions.

Remember: ageing is multi-causal. If you only look at capacity, you overlook the internal resistance – this limits performance and heats up the cell.

5) Service life forecast: from “thumb value” to reliable statement

Data – nothing works without it

Good prognosis separates calendar and cycle ageing, varies SoC and temperature and maps real duty cycles. Clean protocol fidelity (C-rate, pauses, temperature) and control of cell scattering (binning) are important.

Model paths (combinable)

- Semi-empirical: Fit of proven fade laws (e.g. √t proportions for SEI growth) – fast, robust in the validated range.

- Equivalent circuit diagram/EIS-driven: Disentangles ohmic, charge transfer and diffusion components – strong for SOH tracking.

- Physical (P2D/DFN approaches): High quality in parameterization; useful in development/material evaluation.

Managing uncertainty

- Forecasts need confidence intervals and cross-validation via temperature, C-rate, SoC window.

- Pack-level effects (cell scattering, balancing, thermal gradients) add up – cell ≠ pack.

Note: Prediction = test design + model + honesty. A number without context is not a forecast.

6) Safety: error patterns, triggers, countermeasures – at cell level

What can go wrong

- Internal short circuit: metal particles, burrs, separator defect, Li-plating dendrites.

- Overcharge/overtemperature: exothermic side reactions release oxygen/heat → Thermal runaway.

- External influences: Crash, nail penetration, heat sources near cells.

How the cell protects itself

- Separator shutdown (PE melt closes pores) reduces current flow with moderate temperature rise.

- Additive design (SEI/CEI): stabilizes interfaces, reduces gassing and transition metal migration.

- Constructive measures:

- Cylindrical: CID (Current Interrupt Device) and vent for pressure reduction, partly PTC (Positive Temperature Coefficient) in the cover path.

- Prismatic: defined vent lines and gas paths.

- Pouch: controlled degassing in the production process; sealing/tightness is critical.

Detection & operation

- Early detection: Temperature gradients, DCIR jumps, unusual voltage recovery after load – indications of internal faults.

- Operation in the SOA (Safe Operating Area): SoC window, current limits, temperature window.

- Interaction with BMS: Cell monitoring and gentle derating instead of hard shutdown in limit states (stability of the periphery).

Remember: Cell safety is material + design + operation. First prevent, then limit, then discharge in a controlled manner.

7) Testing & evaluation logic – technical, not formalistic

Without expanding on the “qualification plan”, three principles for serious safety assessment and cell evaluation:

- Relevant tests instead of showcases: performance, cycle and temperature tests under realistic limits; abuse tests (overcharging, external heat, short circuit) with defined termination criteria.

- Documented boundary conditions: Temperature, SoC, C-rate, pauses, fixture – this is the only way to ensure reproducible results.

- Traceability & plausibility: correlate process data (e.g. moisture, drying, calender window) with cell parameters. Results must be cause-consistent.

8) Practical takeaways (compact)

- Characterization: Always carry DCIR + EIS; OCV-SoC curves are mandatory for BMS calibration.

- Design choice: System compromise of installation space, thermal, performance, propagation; not ideological, but component-oriented.

- Mechanics: Define and maintain compression window; design contacting for low contact resistance.

- Aging: Temperature and SoC window are the biggest levers; avoid fast charging cold.

- Lifetime prediction: Semi-empirical + EIS is practical – with clear validity and uncertainties.

- Safety: prevention before reaction; shutdown concepts, additive chemistry, safe gas paths – think cell life.

Conclusion

Battery cells are material + design + process + operation – and it is precisely in this order that requirements should be considered. Reliable characterization makes cells comparable; the design defines integration and thermal margins; mechanics determine resistances and hot spots; aging is multi-causal and must be understood in the real load collective; service life can be reliably predicted if data and model match; safety is not a test step, but a design goal.

For electrical engineers and those responsible for battery production, this means that those who understand cells at this level build systems that are efficient, safe and economical – in the laboratory, on the line and in the field.

PS: Our recommendation: Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 things you need to know in advance about the high-voltage qualification of your employees” is available here (click).

Leave A Comment