From peak power in trains to zero emissions in ports – what engineers need to know about safety, BMS and system design.

Electrified off-road applications are growing rapidly – from shunting locomotives to harbor tugs. This technical article summarizes the tough technical guidelines for lithium-ion battery systems in aerospace, rail and marine applications – with a focus on design, operational safety and the standards environment.

1) Application scenarios and load profiles – what the application specifies

Experts outline “further areas of application” for (ev) high voltage where recuperation, hybridization and the significantly higher performance of Li-ion compared to lead-acid offer real system advantages. Typical examples: frequent acceleration/braking in rail transport, lifting/lowering of port cranes, battery-buffered diesel-electric drives (e.g. locomotives, cranes, ships) and tractors on airport aprons.

Implications for the load profile:

- Rail: High cyclical power requirements with recuperation peaks; on electrified lines, feeding power back into the grid is often more energy-efficient – batteries are particularly worthwhile on non-electrified sections or for peak shaving/start support. Rail vehicles also require classic IEC/VDE qualification and consideration, and are explicitly NOT included in the scope of DGUV I 209-093.

- Ships/sea: Hybridized diesel-electric systems allow downsizing and operating point optimization of the combustion engine, batteries buffer manoeuvring and hotel loads; at berth, shore power/batteries can reduce emissions. The options for purely electric drives are also increasing, especially for small boats and ships. An analogous application of DGUV I 209-093 is certainly envisaged here. However, despite many similarities, the classic diesel-electric drive should not be confused with a hybrid drive.

- Airside (aviation ground operation): Apron tractors/tugs benefit from high power density and frequent short charging cycles.

Conclusion: Each sub-segment dictates its P/E target (power/energy ratio) and thus cell chemistry, modulation and thermal/BMS design.

2) Cell and system design: from the chemistry to the pack

Cell chemistry & architecture. Experts emphasize that Li-ion covers the specific energies required today for mobile and stationary heavy-duty applications – far beyond classic lead systems. This opens up application windows that were previously “not applicable” (e.g. e-drives in ports/rails).

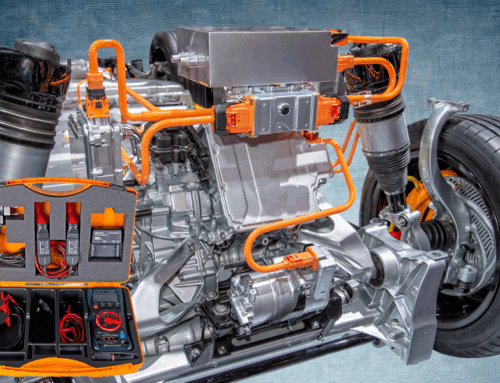

Pack topologies. Diesel-hybrid drives typically integrate the storage system as a power buffer (short-term high C rates), not as long-term energy storage. This influences:

- Cell selection (low internal resistance, robust high-current capability),

- Module/pack contacting (low contact resistance),

- Thermal (locally high heat flows with short power pulses).

Stationary vs. mobile in industrial use. Where there is no grid connection (island solutions), energy storage systems are classified according to discharge rate (time window) and storage capacity; this determines dimensioning and operating strategy.

3) Thermal management and safety – the non-negotiable basics

Control heat flow. Rail vehicles (short distances, recuperation peaks), port maneuvers and airside tugs generate dynamic load changes; the thermal architecture must:

- Minimize hot spots (homogeneous flow/contacting),

- limit ageing-relevant temperature gradients,

- Provide fail-safe strategies for cooling failure.

Abuse robustness & system protection. Mature safety/performance tests exist for road vehicles (IEC 62660-1/-2, ISO 12405, etc.). For marine, aviation and aerospace applications, the standardization overview explicitly points out that dedicated standards must be developed/established – i.e. manufacturers and operators must now take particular care to define their own safety specifications from cell to system level and harmonize them with authorities/acceptance.

Transport safety as a context. Even the transportation of used/defective batteries is subject to strict dangerous goods regulations; defective energy storage systems are in some cases completely prohibited in air freight (IATA/ICAO) (special provision A154). These regulations underline the level of safety required in aviation-related applications, including during operation.

4) BMS functions: from recuperation to protection logic

Monitoring & protection. In all three domains, cell voltage/temperature monitoring, current limiting, balancing and fault detection are basic requirements. For road vehicles, the testing/verification landscape is detailed (ISO 12405, ISO 6469-1, etc.); marine/air-specific verifications are being developed – resulting in a higher integration/verification effort on a project-specific basis (e.g. fire compartments, SHIP/AERO conformity).

Performance management.

- Rail: BMS must safely accept high recuperation currents (state-of-charge window, temperature window) and actively prevent overcharging.

- Ships: load jumps during maneuvering; BMS orchestrates battery↔generator to keep diesel in efficient range and reduce noise/emissions.

- Airside: Many short cycles/downtimes → pragmatically optimize SoC window and intermediate charging.

5) Mechanics & integration: Vibration, shock and environmental influences

Rail: Permanent vibration/shock requires robust module mounts, defined cable paths and connector systems with vibration protection; air flow must remain stable even in a contaminated environment (close to the station/particles). (Motivation: described in the text as dynamic applications with frequent acceleration/deceleration).

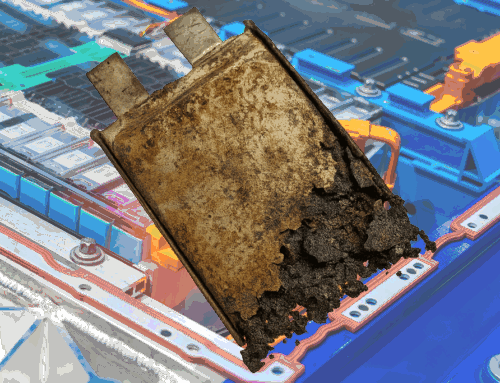

Ships: Exposure to corrosion/salt spray, condensate and confined engine rooms should not be underestimated and are an argument in favour of encapsulated, serviceable packs with condensate drainage and IP protection concept; shore power connection for port laytime minimizes emissions.

Airside: Wide temperature ranges, dust/FOD; short service windows → modular, easily exchangeable packs.

6) Difference to road vehicles – short and precise

- Standards environment: Performance, abuse and safety requirements are standardized in detail for electric road vehicles (IEC 62660-1/-2, ISO 12405, ISO 6469-1, ISO 6469-3). A complete catalog of standards must be “established” for ship/air/space travel – i.e. more project-specific derivations, approval and acceptance processes.

- Load profile: car/bus → mixed driving profile; rail/sea/airside → clear peak/recu focus or hotel loads/maneuvers.

- Integration: Road vehicles use established platform packages; marine/rail/airside require more customized installation spaces, protection types and maintenance access.

7) Operation, maintenance, service life

Operating window: Tightly controlled temperature and SoC windows reduce ageing – especially for high-performance profiles with many short charge/discharge pulse sequences.

Maintenance & interchangeability: Modularity and rapid interchangeability (e.g. airside fleets) increase availability; in port/rail, standardized assemblies facilitate condition diagnostics and warehousing.

Energy/charging management: On tracks with overhead lines, regenerative braking is often more efficient; batteries primarily take on buffer/peak tasks or serve as hybrid energy storage in non-electrified sections.

8) Safety by design: layered model instead of individual measures

The source implies a multi-layer concept: cell selection ⇢ module mechanics ⇢ pack fuses ⇢ BMS shutdown ⇢ thermal ⇢ installation environment. IEC/ISO already specify Abuse tests for road vehicles – for ships/aviation, the systematic transfer to the domain standards is the central task (fire protection sections, evacuation routes, smoke/gas routing, etc.).

Consider the transport and logistics chain. Strict dangerous goods regulations apply even before commissioning; damaged batteries, for example, are excluded from air freight – this is part of comprehensive safety planning (repair, return transport).

9) Compact practical guide (engineering check)

- Load analysis: record peak power, recuperation profiles, hotel loads, cycle types. (rail/port/airside.)

- Define P/E target: High-performance buffer vs. energy carrier → Derive cell selection/configuration.

- Design thermals: Worst-case pulses, homogeneity, fail-safe for cooling defects.

- BMS logic: limits, balancing, recuperation assumption, error modes.

- Mechanics & environment: Vibration/shock (rail), salt/condensate (sea), dust/FOD (airside).

- Standards & approval: Existing IEC/ISO for road vehicles as reference; derive marine/air-specific requirements on a project-specific basis, as standards catalog “under construction”.

- Operating concepts: SoC window, fast charging window, interchangeability, regeneration strategies.

10) FAQ

- Where are lithium-ion batteries used outside of road traffic?

Increasingly in rail vehicles, ships and aircraft ground vehicles (airside tugs). Typical applications include hybridized diesel-electric systems, shunting locomotives, port cranes and airport tractors.

- How do the load profiles of these applications differ?

- Rail: High cyclical power requirements, recuperation peaks, partial grid regeneration.

- Ships: Strong load jumps during maneuvering, hotel loads, emission reduction through shore power.

- Airside: Short, frequent charge/discharge cycles and fast charging windows.

- Which cell chemistries and system designs are suitable?

Li-ion systems offer the required specific energy and performance. The decisive factor is the P/E ratio:

- Power-oriented (e.g. hybrid buffers in locomotives) → low internal resistance, high C-ratios.

- Energy-oriented (e.g. long-term operation at sea) → high energy density, optimized cooling.

- What role does thermal management play?

Homogeneous temperature distribution is critical. Systems must avoid hotspots, minimize ageing and include fail-safe concepts for cooling failures.

- How do the safety standards differ from those in road traffic?

Mature standards exist for cars and buses (e.g.

- Which BMS functions are indispensable?

Monitoring of cell voltage, temperature and current, balancing, fault detection and recuperation management. The BMS is the central protection and control instance of the system.

- What environmental influences need to be taken into account?

- Rail: Permanent vibration, dust, shock load.

- Ships: Corrosion, salt, condensate – require encapsulated, maintainable systems.

- Airside: Wide temperature range, dust, FOD – modular design recommended.

- How is security achieved in the overall system?

Through a layered concept: from cell selection to packing mechanics, fuses, BMS shutdowns and thermal management through to the installation environment.

Transport and dangerous goods regulations must also be taken into account (e.g. IATA Special Provision A154).

- Which maintenance strategies make sense?

Modular assemblies, quick replacement and narrow operating windows (SoC, temperature) extend the service life and ensure high availability – especially in fleet operation.

- What is the most important conclusion for engineers?

Those who develop systems based on the load profile, prioritize thermal and BMS as safety-critical and take the standards and transport regime into account at an early stage will achieve safe, efficient and sustainable solutions – from peak power in trains to zero emissions in ports.

11) Conclusion

Lithium-ion batteries have a wide range of applications outside of road transportation: Hybridized or hybrid-like diesel-electric drives in rail and shipping, low-emission port/airport logistics and buffer functions in non-electrified sections. What they have in common is a power- and thermal-driven design with a robust BMS – but with different levels of maturity in terms of standards: while electric road vehicles have mature IEC/ISO test catalogs, the marine, aviation and aerospace sectors still need to establish dedicated standards and ensure project-specific compliance. Those who consistently think about their design in terms of the load profile, prioritize thermal/BMS and plan the approval/transport regime at an early stage will achieve safe, efficient systems – and use precisely those strengths that made Li-ion possible in these domains in the first place.

Note on the source basis: The statements summarized here are based on the sections on “Fields of application/other areas of application” (incl. port/rail/airport) and the overview of standards, which lists a catalog of standards yet to be established for shipping/aviation/space travel.

Anyone who works with (ev) high voltage systems bears responsibility for the safety of people, the environment and operations. Solid training – such as battery diagnostics and the specialist high voltage ( ev ) at TCS – is the first step.

PS: Our recommendation: Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 things you need to know in advance about the high-voltage qualification of your employees” is available here (click).

Leave A Comment