The electrical systems in modern aircraft are highly complex and safety-critical. Unlike in conventional industrial systems, special requirements come into play here – from the network system to frequencies and specific protective measures. For electrical specialists in the production and maintenance of aircraft, this means that they not only need solid electrical engineering training, but also ongoing qualification, which is particularly important in aviation – whether in Switzerland, Germany, America, Asia or any other country with worldwide flight connections.

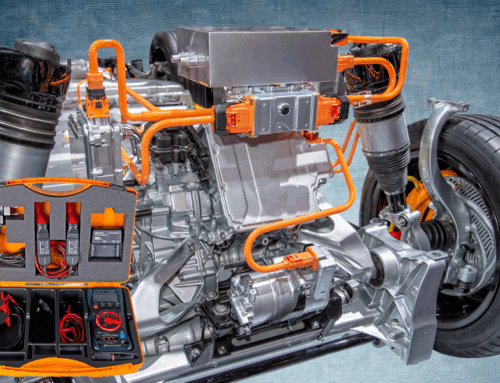

A key technical feature is the grid structure on board. In contrast to the 50 Hz alternating current network on the ground, aircraft generally work with 115 V / 400 Hz AC. This frequency reduces the size and weight of electrical components – a decisive advantage in air traffic. In addition, 28 V DC systems are used, particularly for control units, sensors and emergency power supplies. A large commercial aircraft such as the Airbus A380 or a Boeing 787 requires a continuous electrical output of around 90 to 120 kW to supply all on-board systems in regular operation. In peak load situations, such as during take-off or with simultaneous air conditioning and de-icing, electrical outputs of over 150 kW can be achieved in the short term.

Working on such systems requires special safety measures. VDE 1000-10 makes it clear that anyone working as an electrical specialist must not only acquire their specialist knowledge once, but must refresh it regularly. This applies to both theoretical understanding and practical know-how – for example, when dealing with typical aviation plug connections, protective relays or live components during maintenance work.

At the same time, the Occupational Health and Safety Act (ArbSchG) requires a targeted risk assessment and specific instructions. The German Ordinance on Industrial Safety and Health (BetrSichV) and DGUV Regulation 3 make it clear that electrical equipment in aviation is subject to strict inspection deadlines, special documentation obligations and requirements regarding the qualifications of inspectors. This applies in particular to the separation of control and power circuits, earthing strategies and protection against residual energy and short circuits.

Only those who understand the special features of electrics in their specialist area as well as the changes in the world of standards and undergo regular further training can safely install, maintain and test these systems. It is the employer’s responsibility to demonstrate the maintenance of professional competence in all areas.

After all, it is not only economic success that is at stake in aviation, but also the safety of human lives at every stage.

This was a brief insight into the standards beyond VDE for the qualified electrical specialist. Knowledge of international and European electrical engineering standards is part of the basic knowledge of a qualified electrical specialist and is also mentioned in the maintenance of professional competence course for electrical specialists, which is taken very seriously by highly sensitive industries such as aviation.

PS: Our recommendation: Various providers also offer courses, such as the aforementioned “Maintenance of professional competence for electrical specialists” or the “Recurring instruction for the electrical specialist (annual instruction)”. More information on this can be found on our homepage www.tcs-engineering.de We offer various open seminars as well as customer-specific in-house seminars.

“End!” and an ES must be called in. This means that any troubleshooting NOT provided for, i.e. free troubleshooting, may only be carried out by an electrical specialist. The ESfdt should also be regularly kept up to date. Participation in a maintenance of professional competence course is definitely an option. We are also happy to offer you specialized services.

Our free(REALLY free, even WITHOUT having to provide an email address!) paper “5 things you need to be clear about before you qualify and deploy your employees for electrical work.” is available here (click).

If you would like to know more about the different roles, in particular those of the EiP, ESfdt, ESfdt and especially those of the CRES and their interaction, I recommend our publications, for example the audio book “Die Verantwortliche Elektrofachkraft: CRES-Struktur und Betriebliche Elektrosicherheit für Unternehmer, Fach- und Führungskräfte”. Information and sources of supply can be found on the usual audiobook portals and on the homepage tcs-engineering.de

Leave A Comment