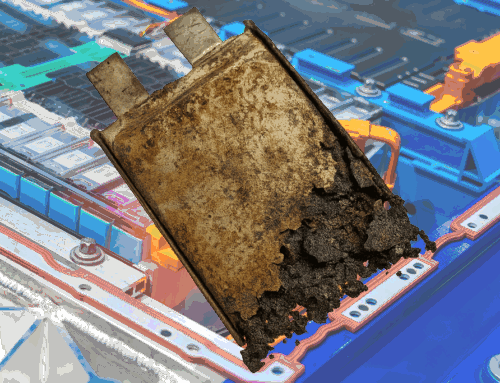

High-voltage batteries in electric vehicles are generally long-lasting. They should be, but removing them is a huge effort.

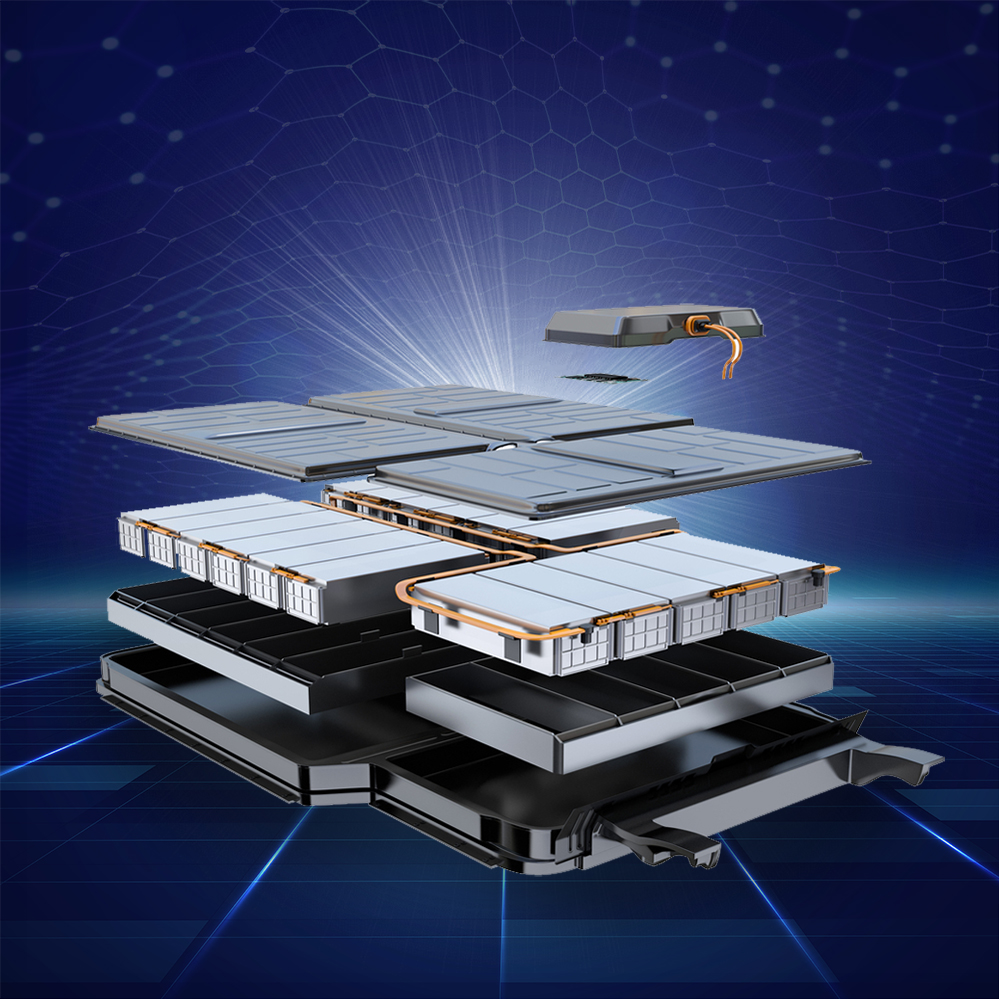

The high-voltage battery – generally also referred to as the traction battery – stores the full energy required by a purely electric vehicle without other types of drive. It is therefore also largely responsible for the so-called range. As customers want as long a range as possible, a great deal of attention is paid to it in development and production. As we have already been able to support and qualify several battery factories, we can say from experience that the manufacturers put a lot of effort into the batteries; and despite all the optimizations, they are by far the most expensive components of an electric vehicle.

It is therefore very obvious that batteries cannot be regarded as an ordinary component: A repair seems to make more sense than a replacement with a new high-voltage battery.

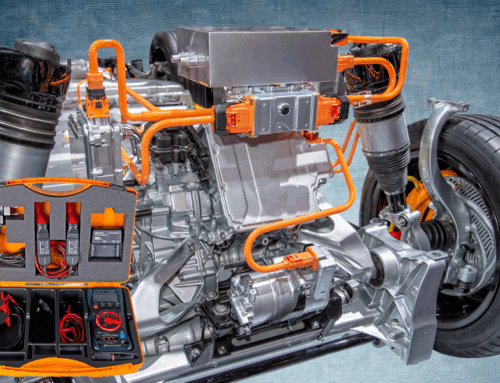

This requires employees who are qualified and therefore well-trained for high voltage work to open the traction battery and replace individual battery modules or defective parts such as components of the battery management system (BMS).

For this purpose, colleagues must not only be trained for high-voltage activities in accordance with DGUV I 209-093 Level 2E or Level 2S, but also for live line work in accordance with Level 3S or Level 3E.

However, not every HV (ev) battery repair employee needs to have the full qualification program. Only employees who actually open the battery and replace components or carry out other “open-heart” repairs must have level 3E or level 3S.

Colleagues who only carry out work on and with (ev) high voltage batteries, where they do not run the risk of coming into contact (even accidentally) with live parts, only require qualification in accordance with DGUV I 209-093 Level 2E or Level 2S.

Colleagues who do not carry out any (electrotechnical) activities (such as repairs) on the (ev) high voltage batteries, but only perform nearby or logistical tasks, only require the level 1E or 1S qualification, which lasts a few hours.

And when an S and when an E as training for the (ev) high voltage batteries and their repair?

Let’s make it simple: As long as you only work with batteries from series vehicles (e.g. in a workshop for electric vehicles such as electric buses or electric trucks), the high-voltage training courses according to the S levels are sufficient.

However, as soon as you come into contact with batteries from production and development – including test vehicle components – qualification in accordance with the LLW levels is required for every employee.

We believe that repair and recycling will become increasingly important in the future.

Our goal in every single high-voltage training course is simple: we want every person who has completed an HV (ev) qualification with us to be able to work safely on HV systems, taking care of the safety of themselves and their colleagues.

We offer all high-voltage courses, such as the aforementioned “Specialist high voltage (ev)” course or the short course to become a specialist high voltage (ev) instructed person. More information on this can be found on our homepage www.tcs-engineering.de In addition to a number of open seminars, we also offer customer-specific in-house seminars: Your high-voltage training from us for you!

Leave A Comment