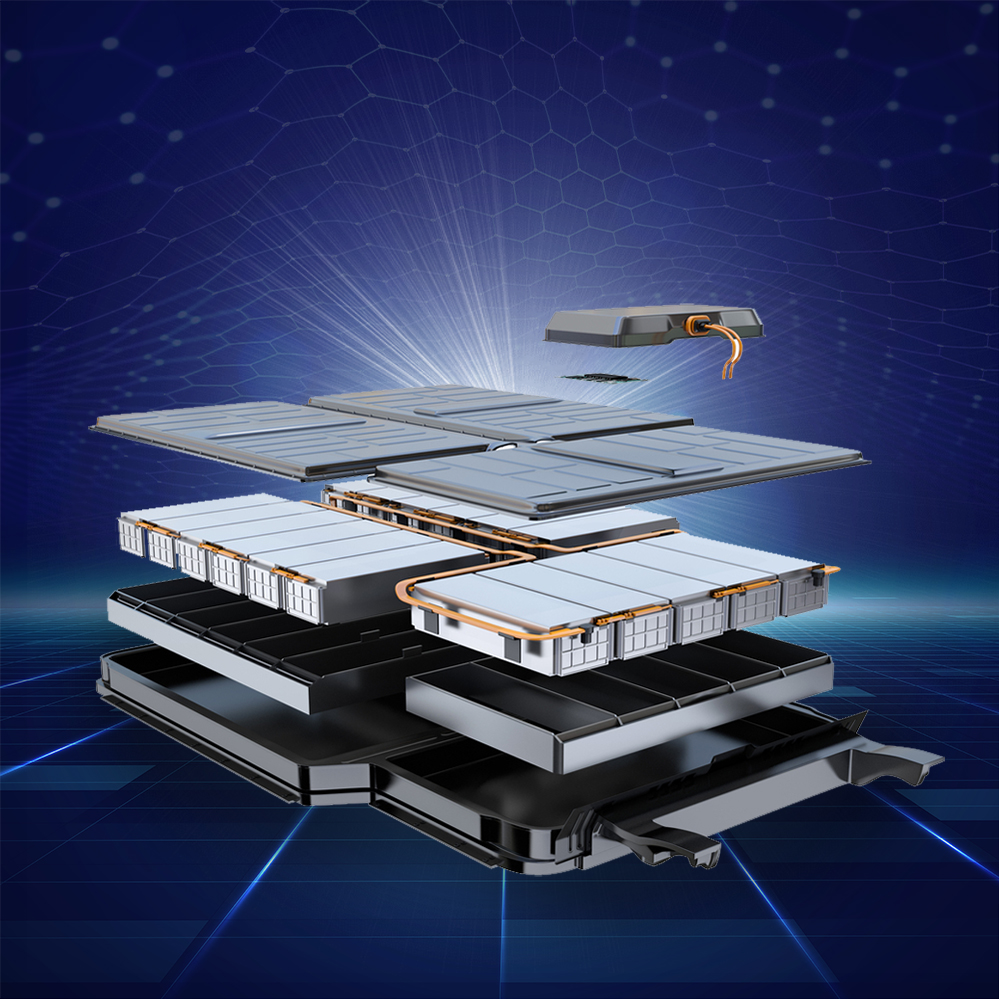

Energy storage in transition: from classic rechargeable batteries to the material basis of modern lithium-ion technology

Why energy storage systems are becoming increasingly important

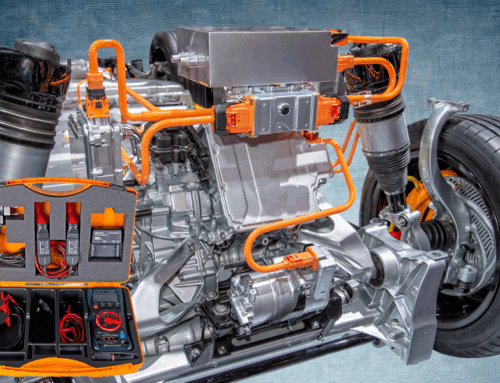

The electrification of almost all areas of life and industry would be unthinkable without powerful battery systems. From smartphones and tools to (ev) high voltage or electric vehicles and stationary storage systems for grid stabilization: batteries form the backbone of modern technologies.

Energy storage is not a young discipline. It is the result of a long development that has led from simple primary cells to lead and nickel accumulators to the lithium-ion batteries that dominate today. For specialists in development and production – whether in automotive, high-voltage systems, energy supply or industrial plants – the question arises: What lessons can be learned from this development – and which material decisions determine the performance of today’s systems?

Classic systems: strengths and weaknesses

Primary cells: the beginning with zinc

The first electrochemical energy storage devices to find their way into everyday life were non-rechargeable cells. Zinc-carbon or alkaline-manganese batteries supplied currents for bells, flashlights and radios. They were cheap and easy to manufacture, but hardly suitable for repeated charging and limited in their power output.

Lead accumulator: workhorse with weight

The next step was the lead accumulator. It impressed with its robustness, reliability and comparatively low costs. Even today, it is still an indispensable price-performance winner in starter batteries or in emergency power systems, but rarely in (ev) high voltage. Its disadvantage: high weight (or mass-to-volume ratio) and low energy density (both in terms of volume and weight) as well as low fast-charging properties – increasingly a stumbling block for mobile applications.

Nickel and sodium systems

Nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries enabled a higher energy density and better cycle stability. They were widely used in portable electronics and hybrid vehicles. Nevertheless, they suffered from environmental problems (cadmium) or limited capacity. Although NiMH also made a guest appearance in (ev) high voltage vehicle technology, today private individuals are more likely to find them just outside the supermarket checkout under “rechargeable batteries” than AA or AAA batteries.

Complementary technologies

Not every field of application is covered by accumulators alone.

- Redox flow batteries offer almost unlimited scalability thanks to liquid electrolytes and external tanks, but are primarily suitable for large-scale stationary storage systems, especially as the energy density is nowhere near that of lithium. So far, HV (ev) e-mobility has primarily been characterized by big promises and marketing bubbles without much real substance.

- Double-layer capacitors (supercaps) boast extremely high power density and short charging times, but are limited in the amount of energy they can store – more of a super-fast peak load than an energy store in the user’s sense.

These systems do not act as a replacement, but as a supplement: they serve special requirements, while lithium-ion systems cover the broad masses – in the private sector, especially in HV (ev) systems such as high-voltage vehicles (e-vehicles) or PV storage systems.

Lithium-ion systems: The dominant standard

Lithium-ion batteries have replaced almost all other systems in many applications over the last three decades. The reasons for this are

- High energy density of over 250 Wh/kg, significantly higher than lead or nickel systems,

- High cell voltages of around 3.6-3.7 V, which allows a compact design,

- Scalability from tiny button cells to megawatt storage systems,

- Good cycle stability with thousands of charging cycles, depending on material and operating strategy.

Their versatility allows them to be used in smartphones, power tools, electric vehicles and industrial storage applications alike.

A look into the future

Further development is in full swing. While today’s cells are exploring their performance limits in terms of safety and energy density, new horizons are opening up:

- Lithium-sulphur batteries promise twice the energy density, but are still struggling with cyclization problems.

- Lithium-air systems could theoretically store even more energy, but are currently unstable and difficult to control.

But please be careful, I myself have been reading about “the breakthrough” in specialist publications for more than 15 years – it is continuing steadily, but not in the revolutionary leaps and bounds that are often advertised. In practice, this means that lithium-ion will remain the dominant platform in the medium term, even if new approaches are being tested in research and pilot projects.

Materials as a success factor

The real strength of lithium-ion technology lies in its material diversity. Different material combinations enable adaptation to a wide range of applications.

Cathodes: the energy suppliers

The choice of cathode material determines the voltage and capacity:

- Lithium cobalt oxide (LCO) provides high energy density, but is expensive and safety-critical.

- Nickel-manganese-cobalt oxides (NMC) combine energy density, performance and service life – the standard in electric vehicles.

- Lithium iron phosphate (LFP) offers a high level of safety and a very long service life, albeit with a lower energy density – preferably in buses and stationary systems.

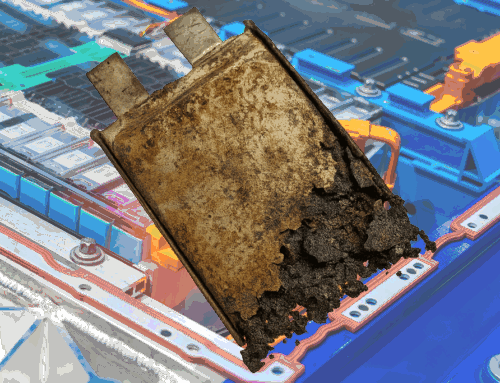

Anodes: memory with development potential

The dominant anode is graphite. At around 370 mAh/g, it achieves solid values. However, attention is increasingly turning to silicon anodes, which enable a significantly higher capacity. The problem: strong volume growth during charging, which can lead to mechanical stress and loss of stability.

Electrolytes and separators

The electrolyte usually consists of organic carbonates in which lithium salts such as LiPF₆ are dissolved. It determines the ionic conductivity and temperature window.

The separator separates the anode and cathode electrically, but allows the transport of ions – a key factor for safety and performance.

Invisible helpers: passive materials

Even seemingly unimportant materials make a decisive contribution to function:

- Collectors made of copper (anode) and aluminum (cathode) ensure current dissipation.

- Binders connect active material and provide mechanical stability.

- Housing materials prevent moisture ingress and outgassing.

One particularly important phenomenon is the formation of the SEI layer (Solid Electrolyte Interface) on the anode surface. It is formed during the first charge, protects the material from further electrolyte degradation and stabilizes operation – even if lithium is consumed once for this purpose.

Practical consequences for development and production

These interrelationships result in clear requirements for specialists in the industry:

- Material expertise: Only with sound knowledge of cathode, anode and electrolyte chemistries can systems be optimized for specific application profiles.

- Process control: Even small deviations in coating, separator quality or electrolyte purity can have a massive impact on performance and safety.

- Quality assurance: End-of-line tests, strict standardization and contamination control are essential.

- Safety awareness: Handling highly reactive materials requires clear work processes – from cell production to integration into systems.

This makes it clear that the choice of materials is not a theoretical issue, but a daily practice in development and production.

Conclusion

The development of electrochemical energy storage systems shows the continuous path from simple, non-rechargeable cells to the highly complex lithium-ion systems of today. One thing remains constant: material and system design determine success or failure.

For engineers and foremen in industrial production, this means that those who master the material basis also control the performance, service life and safety of modern battery systems.

Lithium-ion technology is therefore not only state of the art – it is the platform for future innovations in electromobility, industry and the energy sector, which is why it is so important in (ev) high voltage training courses. PS: Our recommendation: Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 things you need to know about the high-voltage qualification of your employees in advance” is available here (click).

Leave A Comment