Equipotential bonding in the (ev) high voltage system:

A central element of high-voltage safety

In any (ev ) high voltage training course, measuring equipotential bonding is a key exercise. Equipotential bonding within an HV (ev) component as well as equipotential bonding between any two high-voltage components in an electric vehicle. Specifically, between the housings, as the bodies of the respective high-voltage components. The potential equalization resistance is determined with a so-called milliohmmeter. Good milliohmmeters work on the basis of the so-called four-wire measurement. (This is not to be confused with the three-wire measurement, which is mostly used for measuring ground resistances).

Every electrical specialist (ES) as well as specialist for high voltage systems (FfHV)/specialist high voltage (SHV) is therefore used to handling the milliohmmeter. According to section 5.1 of UN ECE R 100, “the equipotential bonding resistance between any two exposed conductive parts must be less than 0.1 ohms.” This is thus a rather strict regulation, the meaning of which will be briefly explained here.

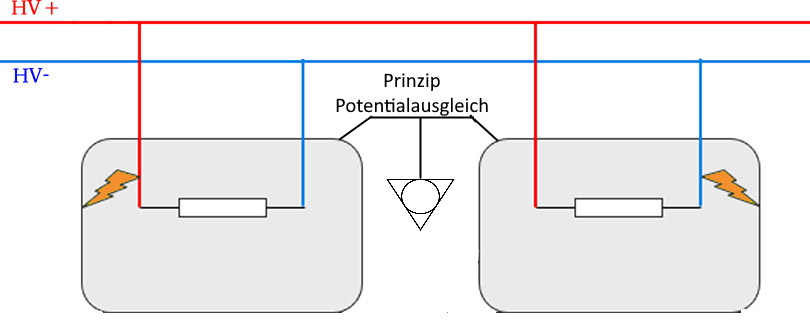

The high-voltage network is an IT-like network; accordingly, both HV+ and HV- are galvanically isolated from the vehicle ground and all equipment bodies.

If a short circuit should occur in a high-voltage component (regardless of whether HV+ or HV-), there would initially be no danger, since no electrical circuit is closed due to the galvanic isolation. This alone provides a certain level of security. However, high-voltage safety is characterized by the particularly high level even in the unlikely worst case.

If a second body short circuit of the other pole should occur at a different location, the short circuit current must be able to flow stably via the equipotential bonding so that the HV (ev) fuse within the high-voltage battery can trip safely.

Example: There is a body short circuit of HV+ within the power electronics and later a body short circuit of HV- at the high-voltage battery itself.

Since both vehicle ground, high-voltage battery body and power electronics are conductively connected to each other via the equipotential bonding, a short-circuit current will flow via the equipotential bonding and can trigger the HV fuse of the battery. The equipotential bonding must therefore also be able to withstand corresponding loads, which is an important factor in addition to the pure resistance value.

However, the equipotential bonding has another function; it enables the insulation monitor to detect an HV (ev) fault at any point on the vehicle. Since insulation monitoring is only performed at one point on the vehicle, a fault against any component can be detected thanks to equipotential bonding. This means that errors are detected at an early stage and can be corrected long before a worst-case scenario can occur. There will certainly be a separate article on the subject of insulation measurement.

Equipotential bonding thus fulfills central safety tasks in the (ev) high voltage vehicle, which is why it is so important in high voltage training courses.

PS: Our recommendation here: There are also courses offered by various providers, such as the aforementioned course “Specialist high voltage (ev)” or also the small course for the specialist instructed person for high voltage. More information about this can be found on our homepage

www.tcs-engineering.de

We offer various open seminars as well as customer-specific in-house seminars. Of course, the measurement of equipotential bonding is one of the standard exercises of the SHV qualification: everyone measures the equipotential bonding resistance. :-)

Our free(REALLY free, even WITHOUT having to provide an email address!) paper “6 Things You Need to Know About High-Voltage Qualification of Your Employees in Advance” can be accessed here (click) .

Leave A Comment